Are you looking for a solution to create smooth, perfect edges on your woodworks? Look no further!

This comprehensive guide for using a disc sander will help you get the job done, quickly and efficiently. You’ll learn all the essentials of disc sanding and how to use it to get professional, polished results.

A disc sander is a useful tool for finishing, sanding and smoothing out wood and other materials. When used correctly it can be an important part of the woodworking process. Its speed, power and size make it an ideal solution for many sanding tasks; it reduces the effort normally associated with hand sanding.

This guide covers how to use a disc sander in order to achieve a smooth, even finish on your project. We’ll examine how to choose the best disc sander for your needs, how to prepare yourself and the job site before you start working with the machine, how to set up the machine properly for successful use, as well as safety precautions and maintenance techniques for long-term operation of your disc sander.

By following these guidelines anyone can learn to use a disc sander successfully and easily create beautiful projects with flawless finishes!

Preparing the Wood

Before you turn on your disc sander, it is important to prepare the wood to be worked on. Make sure that the desired surface is free of any dirt or debris before beginning. You should also ensure that there are no knots, splinters, or rough patches that could cause any issues when smoothing out the surface. You should sand these sections separately with finer grade sandpaper before using the disc sander.

Make sure to check your workpiece closely for any nails or hardware that might have been left in the wood before running through your disc sander. These can ruin a piece if they are not found and removed beforehand. Clearing the area of unnecessary items can help keep your workspace tidy and reduce clutter, allowing for better results from sanding operations.

Use a damp cloth to wipe down the wood surface and remove debris or shavings from previous operations as well as dust and dirt particles from air and ambient sources such as open windows and doors in screened-in areas. The disc sander manual should include clear instructions on how much pressure is adequate to achieve desired results, depending upon type of wood; this depends largely on species and moisture content but is essential for avoiding snags which can ruin the outcome of a project quickly. Following manufacturer’s specifications will always result in optimal finishing operations for better results.

Selecting the appropriate wood for the project

When selecting the type of wood you will use for your project, it is important to consider the end goal. You want it to look beautiful, so selecting the right wood for each part of the project is essential. Hard woods such as Oak, Maple and Walnut will give you a more polished finish compared to soft woods like Pine or Poplar which may require additional sanding.

Before you begin sanding, inspect your wood for any visible defects such as knots that may be harder to sand around or nails embedded in the surface. You also want to make sure that all surfaces are level before beginning so that there are no gouges or uneven edges when finished.

To ensure you get a professional looking finish on your project, remember to always select the right type of wood and inspect it thoroughly before starting your disc sander task!

Cleaning and sanding the wood before using the disc sander

Before attempting to use the disc sander on wood, it is important to clean and properly sand the piece. This will ensure that all large pieces of dirt, sawdust, etc. have been removed and that the wood is free of small splinters, gouges or other blemishes. The best way to do this is by using a combination of hand-sanding tools and clamping tools like the belt sander or drum sander.

Using a medium-grit sandpaper (such as 80-grit) with a belt or drum sander can help smooth out some of the bumps and irregularities in wood quickly and easily. Start with at least one pass over the entire surface, adjusting pressure according to the texture desired. When all areas are uniformly sanded by hand or machine tool, use a vacuum cleaner to remove all dust particles before moving onto the disc sander step.

Tip: For best results when sanding with a belt or drum sander, slightly roughen up the surface before starting for better adhesion of grit particles during sanding operations. This allows for more aggressive materials removal each time without clogging your abrasive paper too quickly!

Importance of wearing protective gear

It is imperative that safety equipment, such as safety glasses and hearing protection, be worn when using a disc sander. The disc sander can create a significant amount of dust and noise, which may cause health hazards. Therefore, it is important to take proper precautions to minimize the risk of injury or other health related issues. Additionally, before operating a disc sander always make sure you read the operator’s manual and familiarize yourself with the device and its operation. This will give you a better understanding of the potential risks involved with using a disc sander and help ensure that it is used safely.

When using the disc sander always keep work pieces securely clamped in position before powering on. Check that the sanding discs are correctly mounted on the spindle and are not damaged in any way as damaged discs have a tendency to wobble or vibrate which could lead to injury or damaging material being worked on. The sanding table should be secured firmly before beginning. During operation make sure that your hands are kept away from any part of the moving components of sanders such as belts and pulleys as these parts can cause serious injury if contact occurs. It is recommended never to use one hand on these power tools since it leaves no room for error should an accident happen. Also keep an eye out for hot surfaces from long exposure to friction which often occur at high speeds associated with power tools like this one; use heat-resistant gloves when necessary.

Setting Up the Disc Sander

Before you start sanding, it is important to properly set up the disc sander. Make sure you adjust the height of the table so that it is level with the sanding belt or disc. Doing this will help ensure that your results are even and consistent.

You should also take a moment to check for any warping in the belt or disc, which could lead to uneven sanding. If you find any warping, readjust the height of one side of the table until it’s even with the other side.

Then, turn on the power and adjust your speed settings using the knob found on most disc sanders. Start by setting it to low or medium speed and gradually increase as needed. You may want to practice on a piece of scrap wood before starting your project so that you can get familiar with how your particular disc sander handles different speeds and pressure levels.

Finally, make sure to place your workpiece against a backing plate before beginning to sand. This will help protect it from being scratched or damaged by the belt or disc while also creating a consistent surface finish for each pass of sanding. Some backing plates are fixed into place near where the disk meets its rotation gearbox inside the machine’s cast iron casing, while others can be easily attached with bolts outside of that space if needed for larger projects.

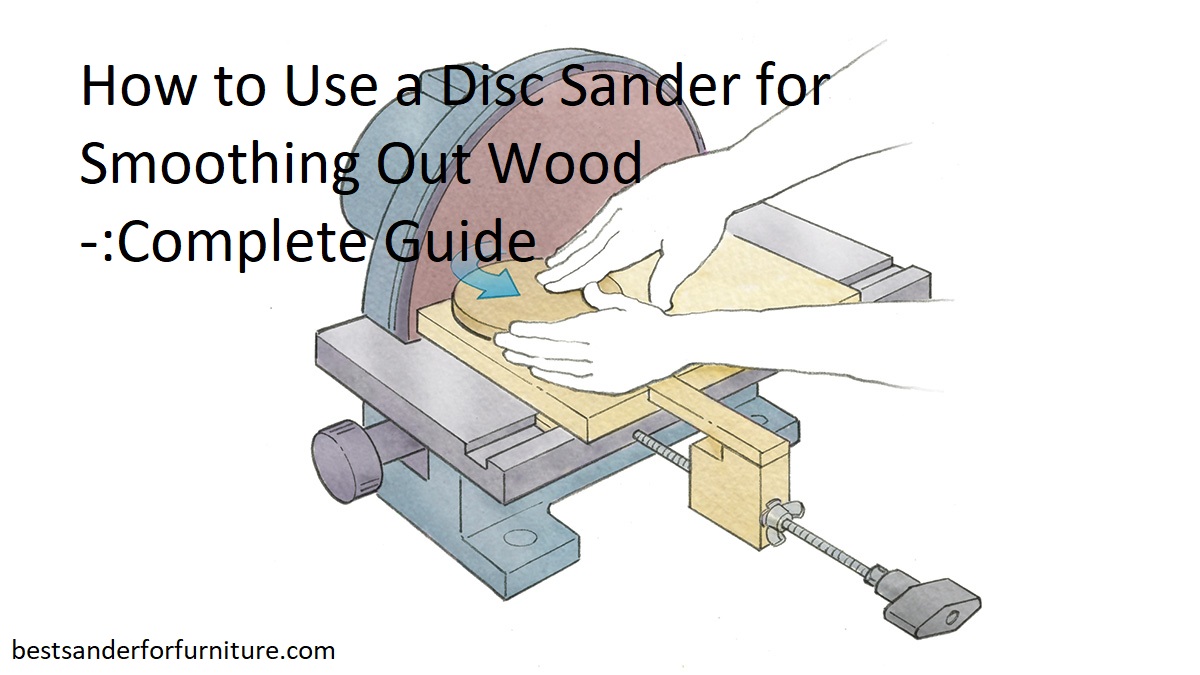

Explanation of the different parts of the disc sander

When it comes to smoothing out wood surfaces, a disc sander is an invaluable tool. It’s a machine that uses a round disc of abrasive material to quickly sand down and correct small imperfections in wooden pieces. With the knowledge of what each part of the disc sander is and how it works, you can properly use the tool to achieve the desired results.

Table – The table is what rests upon the base of the sander, providing a flat and stable surface for wood pieces to be placed on. Most have adjustable settings so that you can modify its height, allowing you greater control as you sand away wood strategically around small objects or tight corners.

Disc Motor – This is the motor which provides rotational energy to spin the circular grinding disc at variable speeds. This ensures that you are able to work with various types of wood and applying different amounts of pressure as appropriate.

Disc Guard – This guard covers most (if not all) edges of the disk so that your hands are protected from harm during usage. Make sure that there are no gaps in which your fingers could poke through; tuck them away when lifting up large pieces and only expose one edge at a time when dealing with smaller ones.

Dust Bag/Vacuum Attachment – This hose-like part attaches either onto a dust bag or vacuum cleaner for collecting fine debris from sanding operations; most come with adjustable nozzles for convenience in tight spaces or hard-to-reach crevices . Make sure you empty it out or unclog it regularly after use.

Steps for setting up the disc sander

Disc Sanders are an essential tool for woodworking and other DIY projects, as they are incredibly helpful in sanding small wooden parts to a perfectly even surface. To ensure the best results possible, it is important to correctly set up the disc sander with regard to the right height of the work table and the disc itself. Here we will provide a complete guide as to how you should adjust your disc sander before starting any project.

Before setting up the disc sander, make sure it is in good working order. Check that all knobs and screws on the machine are secure, and that all safety features (such as shields) are all properly in place and working correctly.

To begin setting up your disc sander, start by making sure you have enough room on your workbench or table for both the tool itself (center it if possible) and any wood pieces you plan on shaping with it. Securely attach one end of your work piece to an adjustable hold-down clamp connected firmly to your sander’s table with two screws per clamp: one at top center of the clamp and one at bottom center, using a ¼- or 3/8-inch hex head wrench.

Next adjust the height of your sander’s table platform, lifting it as necessary until it is about 1/4 inch lower than spindle head when pushing down lightly next to its edge guide column.

Finally, adjust for squareness by placing a try square against side of spindle head when lowered into position (using levelers provided). Make sure point of contact between head and table top matches point of contact between try square side arm against same contact point on both pieces . If everything looks accurate, lock down clamps onto underside shelf supports with same hex wrench used earlier., tightening until snug but not overly tight.

Adjusting the disc sander to achieve desired results

Before beginning a project on a disc sander, it is important to make sure that the sander is adequately adjusted for the job you wish to do. Sanding too aggressively can result in excessive material removal or heat-related damage to the wood surface. On the other hand, insufficient sanding pressure can result in incomplete smoothing or leave unacceptable marks on the wood.

For best results, consider making adjustments based on four primary variables—belt tension, belt speed, belt contact angle and surface contact area.

- Belt tension: The belt tension should be high enough to provide sufficient resistance against sanding while still allowing the sander to vibrate freely as it contacts and sands your workpiece. If possible, use a torque wrench when adjusting and/or maintaining belt tension according to manufacturer guidelines.

- Belt speed: The ideal speed will depend on the type of material you’re working with and what type of finish you want for your project; for example, higher speeds should be used for hardwoods and low speeds should be used for softer woods like pine or cedar. It’s also important to consider which sandpaper grit you’re using—finer grains generally require lower speeds whereas coarser grains often benefit from higher speeds (always consult manufacturer instructions for proper use).

- Belt contact angle: Along with setting belt tension and speed, another way of producing optimal results is by adjusting the contact angle at which your workpiece comes in contact with the disc sander’s spinning gouge-resistant surface; common angles range from 0° (flat) up to 45° (diagonal). When determining your desired angle , keep in mind that wider angles tend to grind more while narrower angles are useful for removing defects that are deeper into wood grain such as dings or grooves left by saw blades or jointer planes . Always start with a shallow angle first before increasing as needed; doing so will help prevent overly aggressive grinding which could lead to premature wear of both machine surfaces and sandpaper abrasive media .

- Surface contact area: How wide an area of wood is being processed at once should also be taken into account when setting up a disc sander — larger workpieces may require wider areas of grinding than a single spot . Increasingly broader surfaces can help ensure uniform sanding action throughout an entire board or plank , thereby reducing errors caused by localized scratches or imbalances . This strategy can also reduce total grinding time since fewer passes will generally be needed overall.

Techniques for Using the Disc Sander

Using a disc sander correctly and for the intended purpose can help a woodworker create beautiful products and/or repair damaged pieces. Disc sanders are used to smooth and shape the surface of a workpiece, as well as to deburr edges. Before beginning any project with a disc sander, the user needs to come up with an appropriate plan of attack by considering what is required of them while working.

When using a disc sander, there are several techniques that should be employed in order to create quality results. These include:

- Making sure the object is clamped securely into place, which prevents it from shifting or moving when sanding;

- Pressing down firmly but evenly on both sides of the workpiece so that it is cut at an even rate;

- Making sure not to move too quickly in one direction as this could cause gouging or burn marks;

- Using light pressure on delicate areas;

- Paying attention to corners and edges which should be sanded using more firm pressure;

- And following up with more delicate grits if necessary in order to produce an ultra-smooth finish.

Proper hand placement and posture

Using a disc sander requires both the correct hand placement and posture when operating the machine. Proper hand placement and posture are key to completing any task detail with precision, accuracy, and safety. To ensure that these key aspects are met, following these guidelines will ensure an effective and safe use of a disc sander.

Hand placement: Begin by positioning one hand on the front handle of the disc sander at all times. Place your weight over the footplate you are using so that your arms and upper body can easily move to match up with the wood as you must during sanding. Make sure to keep two hands on the front handle so that your weight is balanced while working.

Posture: Keeping good posture is imperative while using a disc sander, as it helps to keep balance while controlling direction and pressure when operating machinery. Always try to stand up straight- keeping your backside from flexing or jumping forward- in order to maintain good control over the movement of your tool. Be careful not to hunch over or lean in too far, as this may throw off balance or cause further strain on your back muscles which can lead to injury if not maintained properly throughout use of a disc sander.

Different techniques for sanding different shapes and sizes of wood

Disc sanders offer a range of advantages for sanding wood, enabling them to tackle many complex shapes and sizes that traditional sanders struggle to. As with any power tool it is important to use the correct technique to ensure the desired result is achieved. Below are some useful guidelines for using a disc sander for different shapes and sizes of wood.

Flat surfaces: When sanding down flat surfaces, such as table tops, you should use an appropriate grit of paper and start from the outside working in towards the centre – this will help ensure an even smooth finish avoiding any unnecessary ridges caused by overlapping passes. Always ensure the disc sander remains in contact with the surface at all times.

Sharp corner or edges: If you are looking to soften sharp edges or corners then you should attach a harder wheel onto your disc sander; this will help create a more consistent rounder shape whilst maintaining control. To accomplish this you will want to move your disc around the edge whilst lightly increasing pressure towards one side – use eye protection when doing this as dust may be thrown into your eyes.

Curved surfaces : For curved surfaces or shapes, attach a belt sander wheel onto your disc sander which can be used like a contouring tool; slowly traverse across each curve keeping an even tension on both sides where possible before moving on to repeat over other areas finally working back inwards towards each starting point creating a neater line overall. When using either of these wheels be sure to adjust your speed setting accordingly ― too low and it won’t cut efficiently, higher speeds risk an uneven result due to wobbling from poor control.

Conclusion

To properly use a disc sander, it’s important to keep the sanding disc parallel to the work surface and make sure it isn’t rotating too quickly or rubbing hard against the wood. It’s also important to select the correct grit of sandpaper for the desired result. Use finer sandpaper for smoother wood surfaces and coarser paper for removing deep scratches and ragged edges.

Overall, a disc sander is a versatile tool that can save time and effort compared to hand-sanding. Skilled craftspeople and DIYers use these handy power tools often, which demonstrates their quality and effectiveness. With careful operation, a disc sander can produce an even finish on any type of wood surface — from rough planks to delicate moldings. Knowing how to use one properly will ultimately help you get the job done right!

FAQ’S

Can you use a disc sander on wood?

Yes, a disc sander can be used on wood.

What is the proper method of using the disc sander?

The proper method of using a disc sander involves holding the wood firmly against the disc while it is in motion, using a steady back-and-forth motion to sand the surface evenly.

Can I use a grinder to smooth wood?

Yes, a grinder can be used to smooth wood, but it may be too aggressive for some applications and may require additional sanding.

What must you never do when using the disc sander?

You should never force the wood against the disc, as this can cause the wood to kick back or cause injury. Additionally, you should avoid wearing loose clothing or jewelry when using the disc sander.

What is the benefit of a disc sander?

The benefit of a disc sander is that it can quickly and efficiently remove material from a surface, making it a good tool for preparing wood for finishing or for shaping and smoothing wood.

What is the main advantage of the disc sander?

The main advantage of the disc sander is that it can remove material quickly and efficiently, making it a time-saving tool for many woodworking projects.

What speed should a disc sander run at?

The speed of a disc sander can vary depending on the model and the application, but most disc sanders run at speeds between 1,500 and 4,000 RPM.

What is the difference between orbital sander and disc sander?

An orbital sander uses a circular motion to sand, while a disc sander uses a rotating disc. Additionally, orbital sanders are typically smaller and more portable than disc sanders.

What is the difference between sanding disc and grinding disc?

A sanding disc is designed to remove material slowly and gradually, while a grinding disc is designed to remove material quickly and aggressively.

Do you need holes in a sanding disc?

Holes in a sanding disc can help to prevent the disc from clogging with dust and debris, allowing for longer and more efficient use.

See more:

- Best random orbital sander 2023

- Best sander 2023

- Best sander for deck 2023

- Best sander for drywall 2023

- Best sander for furniture 2023